Metallized Ceramic Insulator

In recent years, with the rapid development of integrated circuit technology, metal-Ceramic Insulator packaging forms have been increasingly used and occupy a place in the packaging field.

The structure of this type of package shell is basically the same, generally consisting of a base, a frame, a ceramic insulator, leads and solder. In order for the brazing to proceed smoothly, the sealing surface of the insulator in the shell (such as the contact surface between ceramic and parts) must be metallized. This process is called Ceramic metallization. We currently produce a wide range of Metallized Ceramic Components.

-

Brand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:100,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthWhy a silver plating cover on metallized ceramic frame? Sometimes, a few customers asked a silver plating is asked to cover on nickle plating of metallized ceramics. The main purpose is to increase the wettability at brazing process. We are able to...

-

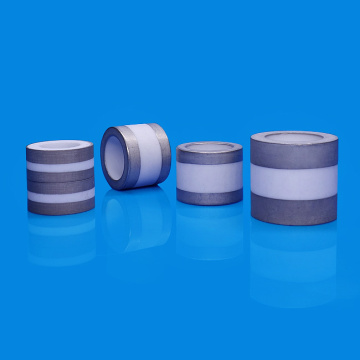

Brand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:100,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthMetallized Ceramics for High Voltage GDT Alumina ceramic parts always work as ceramic housing, ceramic holder,ceramic insulator and output energe windown in variety of electrical vacuum device, it can offer ideal electrical isolation, great...

-

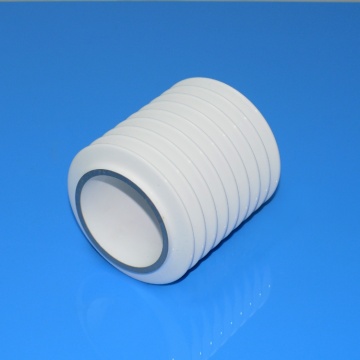

Unit Price:20~100USDBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthCeramic Insulator for Ultra-high Frequency Electron Tubes Jinghui supplies a great many of metallized ceramic insulators, all these metallized ceramics are ideal for use in high vacuum, high current, high voltage and high pressure applications. We...

-

Unit Price:USD 17.5 - 30 / Piece/PiecesBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthMetallized Alumina Ceramic Insulator for Electron Tubes Metallized alumina ceramics are widely used in many different industrial applications because its special function in connection of ceramic to metal and ceramic to ceramic, such as in power...

-

Brand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthAlumina Ceramics for RF Power Feedthrough At present, the commonly used advanced ceramics in electric vacuum devices are aluminum oxide,beryllium oxide,boron nitride, aluminum nitride and diamond. Considering the cost performance, aluminum oxide...

-

Why Air Tightness Is Important for a Metallized Ceramic InsulatorAir tightness is one of the important indicators to measure the quality of Metallized Ceramic Insulator. Air leakage is the main reason for the failure of metal-ceramic insulator packaging shells.

-

What are the reasons for air leakageThe main reasons of air leakage are: 1. Ceramic insulators have quality problems before metallization, which causes air leakage in the insulator itself. 2. Some ceramic insulators are too small (to match the size of metal parts). 3. Problems such as the metallization layer on the sealing surface of ceramic insulators falling off and ceramic being exposed.

-

How to improve air tightnessAir sealing performance can be improved from the following two aspects.1. Strict Control in Production: Products with unqualified quality are strictly prohibited from entering the metallization process.

2. 100% Full Inspection Before Shipment: Pick out insulators that are undersized or have metallization layer defects.