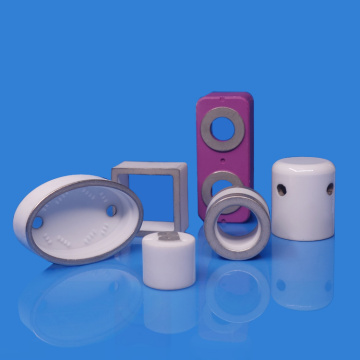

Metallized Ceramic Insulator

In recent years, with the rapid development of integrated circuit technology, metal-Ceramic Insulator packaging forms have been increasingly used and occupy a place in the packaging field.

The structure of this type of package shell is basically the same, generally consisting of a base, a frame, a ceramic insulator, leads and solder. In order for the brazing to proceed smoothly, the sealing surface of the insulator in the shell (such as the contact surface between ceramic and parts) must be metallized. This process is called Ceramic metallization. We currently produce a wide range of Metallized Ceramic Components.

-

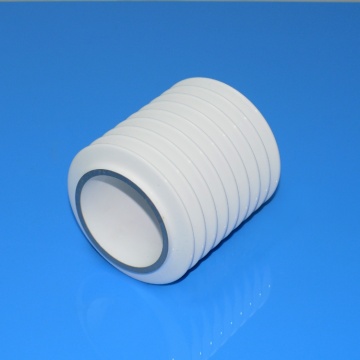

Unit Price:30~200USDBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:100,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthAl2O3 Alumina Ceramic Body for Vacuum Interrupter The alumina ceramic using in vacuum interruper requires superb electrical breakdown strength and idea gas tightness,so it's always shaped by isostatic pressed with excellent dense ceramic body. They...

-

Unit Price:0.25~5USDBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:1000000pcs/monthPlace of Origin:ChinaProductivity:500000pcs/monthMetallization Ceramic Base with Gold Plating for Coil With the properties of high purity alumina ceramic and high frequency anti-high temperature, chemical resistant and non-deformation at any harsh working conditions, metallized ceramic base are...

-

Brand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:2,000,000pcs/monthPlace of Origin:ChinaProductivity:500,000pcs/monthPrime features of metallized ceramic components: 1. Readily accepts Mo/Mn or W metalization for high-temperature brazing of metal to ceramic assemblies 2. Excellent bonding strength over 150 MPa and with ideal leakage rate less than ≤1×10-11 Pa•m3 /...

-

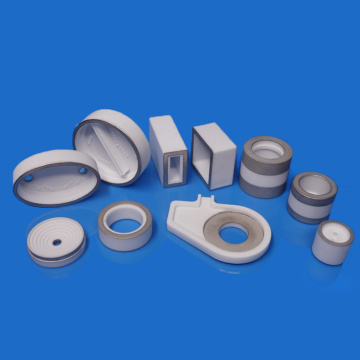

Unit Price:20~100USDBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:2,000,000pcs/monthPlace of Origin:ChinaProductivity:500,000pcs/monthGlazed Alumina Metallized Ceramic Tubing Glazed alumina metallized ceramic tubing is a very special advanced ceramic parts in the high-voltage and high current electronic and electrical application. A metallic layer deposited on the surface of the...

-

Brand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:100,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthWhat is metallization of ceramics? Due to the significant difference of coefficient of thermal expansion between ceramics and metals, It's hardly impossible to bond ceramic to metal directly over in the past many years. In order to get this biggest...

-

Unit Price:USD 0.5 - 1 / Piece/PiecesBrand:Jinghui CeramicsModel No:Standard or custom-madeTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthMetallic Coating Ceramic Insulator for Gastriode Ceramic insulator for gastriode is made of min. 95% alumina, . We have a selective forming processes to produce them according to customer's specific application, specific requirement, such as dry...

-

Brand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthAlumina Ceramic Tube with Mo/Mn Metallization Due to ceramic tube with Mo/Mn metallization can be brazed with metal parts directly, sometimes, a few customers just request alumina ceramic tube to be Mo/Mn metallized. This metallized ceramic tube is...

-

Brand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:50,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthMetallized Ceramics Insulator for Vacuum Electronic Devices The most extensive metallization process for brazing ceramics is molybdenum-maganese method. The metallic layer can be printed on the ceramic body via silk screen, brush, pad way, then the...

-

Unit Price:0.85~20USDBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthHigh Precision Alumina Metallized Ceramic Disk Our facility supplys numerous custom alumina metallized ceramic disk for using based on vacuum interrupting devices and similar applications where ceramic to metal joints of and hermeticity are...

-

Brand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthWhat are ceramics metallization? To solve advanced ceramics to the metals bonding problem, a metallic layer, mainly including molybedenum and tungsten, will be applied on the designated surface of the ceramic body, a very thin metal film on ceramic...

-

Unit Price:0.5~5USDBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:2000,000pcs/monthPlace of Origin:ChinaProductivity:500,000pcs/monthCeramic Insulator for Switch Igniter Discharge Tube Ceramic insulator for switch igniter discharge tube is made of alumina oxides with min. 95% purity, It can be shaped via dry pressing, hot pressing, ISO pressing. In common case, both...

-

Unit Price:USD 30 - 50 / Piece/PiecesBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:100,000pcs/monthPlace of Origin:ChinaProductivity:20,000pcs/monthHigh Precision Large Size Metallized Ceramic Tube We fabricate a great many of customized refractory metallized alumina ceramics for use in vacuum breaker, vacuum electron tubes, vacuum interrupters, power grid tubes and similar applications where...

-

Why Air Tightness Is Important for a Metallized Ceramic InsulatorAir tightness is one of the important indicators to measure the quality of Metallized Ceramic Insulator. Air leakage is the main reason for the failure of metal-ceramic insulator packaging shells.

-

What are the reasons for air leakageThe main reasons of air leakage are: 1. Ceramic insulators have quality problems before metallization, which causes air leakage in the insulator itself. 2. Some ceramic insulators are too small (to match the size of metal parts). 3. Problems such as the metallization layer on the sealing surface of ceramic insulators falling off and ceramic being exposed.

-

How to improve air tightnessAir sealing performance can be improved from the following two aspects.1. Strict Control in Production: Products with unqualified quality are strictly prohibited from entering the metallization process.

2. 100% Full Inspection Before Shipment: Pick out insulators that are undersized or have metallization layer defects.