Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

According to the Maxmize Market Research's data, the global Ceramic Substrate market size in 2021 reached 6.59 billion US dollars, will grow at an average annual rate of about 6.57%, and is expected to reach 10.96 billion US dollars in 2029. As an ideal material for ceramic substrate, aluminum nitride ceramic has a broad range of market, and different product types meet the needs of different applications, among which DBC, DPC,AMB,HTCC and structural Ceramic parts are the main product types.

Due to the rapid development of new energy and electric vehicles, AMB and DBC metallized substrates have risen strongly in the application of IGBT; DPC is favored by high-power LED market; HTCC because of radio frequency, military industry to drive demand growth; The electrostatic sucker used in semiconductor silicon wafers is an important application of lN structural parts. AlN demand will continue to benefit from the fast-growing semiconductor and new energy markets.

With the rapid development of the electronics industry in recent years, the market demand for aluminum nitride powder in China is growing rapidly, and the demand for aluminum nitride powder in China will maintain a growth rate of about 15%, and the domestic market demand will be about 5,600 tons by 2025. The domestic production of aluminum nitride can not meet the market demand, and the powder relies heavily on imports. However, with the deepening of domestic research, aluminum nitride preparation technology continues to improve, the gap at home and abroad is gradually narrowing, and with the strong support of China's policy and the continuous expansion of market demand, the domestic powder industry is advancing to high quality. The following article will explain why aluminum nitride materials can stand out in the Advanced ceramics' family.

Because of its excellent thermal conductivity and thermal expansion coefficient matching silicon, aluminum nitride has become a concerned material in the field of electronics. Aluminum nitride is a hexagonal crystalline zincite covalent bonding compound with excellent thermal conductivity, reliable electrical insulation, low dielectric constant and dielectric loss, resistance to plasma erosion, non-toxic and matching thermal expansion coefficient with silicon. It is not only an ideal material for the packaging of a new generation of heat dissipating substrates and electronic devices, but also for heat exchangers, piezoelectric ceramics and thin films, thermal conductive fillers, aluminum nitride etching shields, aluminum nitride evaporation boats for OLED, etc., with broad application prospects.

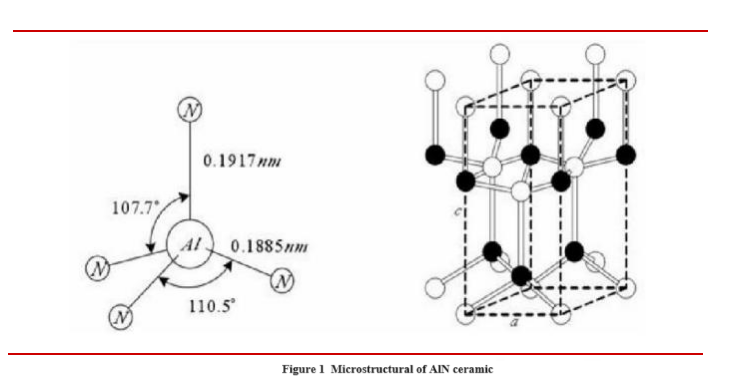

The microstructural of aluminum nitride determines its excellent thermal conductivity and insulation, refer to figure 1.

According to the study "Casting Forming and Sintering Properties of Aluminum nitride Ceramics", due to the small atomic weight of the two elements composed of aluminum nitride molecules, relatively simple crystal structure, good harmonic property, the formed Al-N bond length, bond energy, and covalent bond resonance is favorable to phonon heat transfer mechanism. So that A lN material has excellent thermal conductivity than the general non-metallic materials, in addition, A lN has high melting point, high hardness and high thermal conductivity, and better dielectric properties.

2. The Conducive Strength of Aluminum Nitride

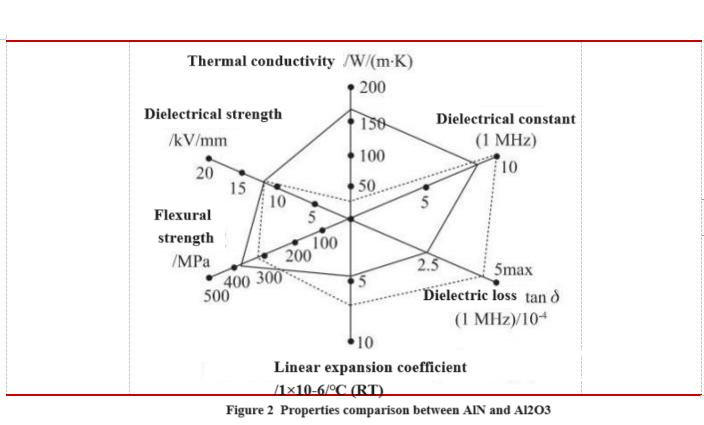

According to the research of "New Progress in the study of the influencing Factors of the thermal conductivity and bending strength of A-LN Ceramics", A-LN has been widely concerned because of its high matching coefficient of thermal expansion with Si, while traditional substrate materials such as Al2O3 are widely concerned because of their low thermal conductivity. Its value is about 1/5 of A lN ceramics and the linear expansion coefficient does not match Si, which can not meet the actual demand, refer to the figure 2.

The thermal conductivity of BeO and SiC ceramic substrate is also relatively high, but the toxicity of BeO is high and the insulation of SiC is poor. As A new type of high thermal conductivity Ceramic material, A lN has the characteristics of thermal expansion coefficient close to Si, excellent dissipative heat performance, non-toxic, etc., and is expected to become an excellent material to replace the ceramic substrate Al2O3, SiC and BeO for electronic industry, refer to the following table for technical data. sheet of several Technical Ceramics

Property AlN Al2O3 SiC BeO Density (g/cc) Thermal conductivity (W/m.k at 25℃) Average Coefficient of thermal expansion (1×10-6/℃) Specific heat 1 x 10^3 J/(kg·K) Mohs Hardness ( GPa) Flexural strength (MPa) Dielectric constant (1Mhz) Toxic or not No No Yes No

3.26 3.9 3.12 2.9 170~320 20~31 50~270 150~270 4.4 8.8 5.2 9.0 0.75 0.75 - 1.046 9 9 9.2~9.5 9 300~500 300~400 350~450 20~40 8.8 9.3 40 6.7 Volume resistivity

(ohm.cm at 25℃)

>1 x 10^14

>1 x 10^14

>1 x 10^15

>1 x 10^14

Jinghui Industry is a professional manufacturer of technical ceramics', we are dedicated to producing various of Precision ceramic components more than 15 years. We believe you'll find an ideal solutions hereby for your project.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.