Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Thermal protection materials are protective materials for daliy life, industrial production and military fields, which need to protect service components working under high temperature or ultra-high temperature conditions to avoid damage or destruction. The thermal resistance principle of the ultra-fine ceramic fiber felt is the no convection effect, infinite shielding plate effect and infinite path effect brought by its distinctive structure. The heat insulation principle is as follows:

1) No convection effect, the porosity of the ultra-fine ceramic fiber heat insulation felt is nano, and the internal air can`t flow freely;

2) Infinite shielding plate effect, nano-scale porosity, infinite porosity wall, minimizing radiation heat transfer to the lowest;

3) Infinite-length path effect, heat conduction occurs along the stomatal wall with the infinite nanoscale stomatal wall.

Due to its unique structure, the ultra-fine ceramic fiber thermal insulation felt has shown excellent performance in many fields such as thermal, acoustics, optics, electricity, mechanics, etc., and has good application prospects in new energy vehicles, aerospace, military, energy and other fields. In the field of new energy vehicles, ultra-fine ceramic fiber thermal insulation felt as a key material for passive protection systems. It is mainly used for physical isolation between battery cells, battery modules and battery packs. In the field of aerospace and military industries, ultrafine ceramic fiber is the vital basic raw material of advanced ceramic composite materials,that's why it is a strategic raw material in the aerospace field and other extreme harsh service environments.

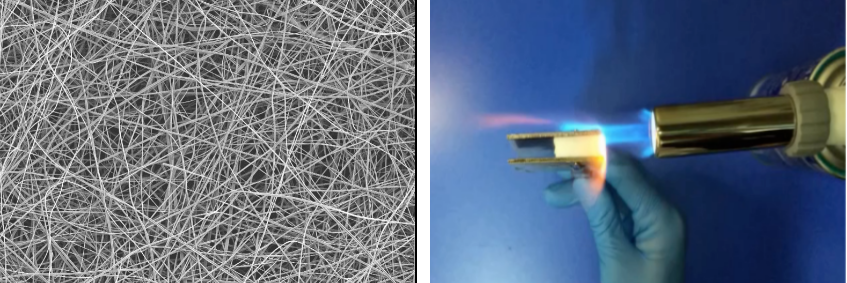

Based on the completely independently developed microfiber spinning industrialization manfacuturing technology, matching equipment and process, the technology of macropreparation of microfiber materials with length to diameter ratio ≥1000 based on gas spinning has been developed. The gas spinning technology uses high-speed air flow to shear and deform the solution (molten liquid), the droplet surface forms a jet, and wind shear and stretch to prepare microfibers. The prepared fiber diameter can be adjusted in the range of 100nm-1000nm. High-speed air spinning technology is suitable for the efficient, controllable and large-scale preparation and production of microfibers in a variety of material systems. It is not only suitable for the manufacture of various polymer microfibers, but also for the manufacture of multi-system microfibers such as metal base and ceramic base. It can quickly improve the production efficiency of microfiber and reduce the unit cost of product. Ceramic fiber cotton with a diameter as low as 100 nanometers, pure inorganic material, maintains good flexibility and elasticity under ultra-high and ultra-low temperature conditions, has no pulverization and slag removal, and has excellent compression fatigue resistance, excellent adiabatic performance and high temperature stability.

At present, the technology is applied to polymer microfibers and filter materials in high-end air filtration, water filtration and other fields; Ceramic microfibers and products for high temperature ultra-light heat insulation in the field of new energy batteries and aerospace; Carbon microfiber fluid collector and electrode materials for electrochemical energy storage fields such as lithium power; Silver microfibers and transparent electrodes for flexible electronics; Technical breakthroughs have been achieved in the fields of functional microfibers for uranium extraction from seawater.

In the civil aspect, ultrafine ceramic fiber materials can be widely used in new energy vehicle protection, power battery safety protection, energy storage battery safety protection, industrial pipeline energy conservation and insulation, building energy conservation, biomedical fields and other industries and fields.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.