Metallized Ceramic Ring

Metallized ceramic rings are usually made from Technical Ceramics, mainly 95% or 99% alumina. Due to the excellent electrical insulation strength, mechanical strength and good thermal properties of alumina ceramics, metallized ceramic rings are often used as Ceramic Insulators / Ceramic Washers in ceramic-to-metal joining applications in high voltage and high current fields.

The most widely used Ceramic metallization method is the sintering of a molybdenum/manganese (Mo-Mn) metal layer followed by nickel plating. We can provide other metal coatings to meet different customer requirements, such as direct silver (Ag) plating on the ceramic body, and tungsten (W) metallization followed by gold (Au) plating.

With our advanced manufacturing equipment, we are able to produce metallized ceramic rings in small to large sizes. We have very high precision processing capabilities in surface grinding, cylindrical grinding and glass grinding, and can meet our customers' strict dimensional requirements.

-

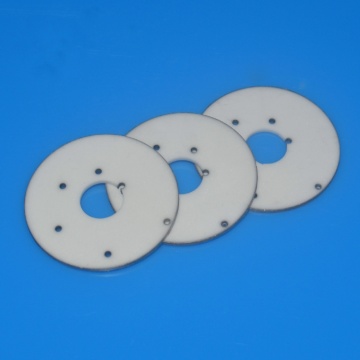

Unit Price:1~5USDBrand:Jinghui CeramicMin. Order:Piece/PiecesModel No:JH.MC.017Transportation:Ocean,Land,Air,Express,ExpressPackaging:Vacuum packagingSupply Ability:200,000 Pieces/monthPlace of Origin:ChinaProductivity:200,000 Pieces/monthMetallized Alumina Ceramic Ring Alumina ceramics have the advantages of high mechanical strength, high hardness, good electrical insulation properties, low high-frequency loss, large thermal conductivity, and good vacuum air tightness. In addition,...

-

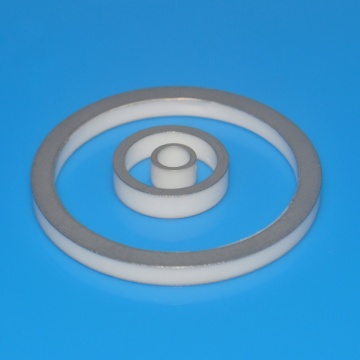

Unit Price:USD 2.5 - 4 / Piece/PiecesBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:100,000pcs/monthPlace of Origin:ChinaProductivity:10,000pcs/monthAdvanced Metallised Ceramic Rings For Electrical Components Metallized ceramic ring for thyristors is commonly made of aluminum oxide ceramics, both end surface coated with a metallisation as base layer which the typical metallisation is Molybdenum-...

-

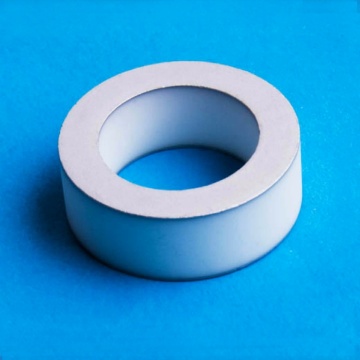

Unit Price:USD 1.25 - 3 / Piece/PiecesBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthDue to all our ceramic metallized parts are with high brazing strength, extraordinary gas tightness, we've obtained much reputation from our customers at worldwide. The metallized ceramics we supplied include ceramic spacer, ceramic cylinder,...

-

Brand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthMetallized ceramic ring covered by metal plating Ceramic-to-metal brazed assemblies are a very common application in high current, high voltage, high pressure vacuum application. Afterwards, metallized ceramic insulator plays a key role in it....

-

Unit Price:USD 2 - 5 / Piece/PiecesBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthThin Film Alumina Ceramic Metallization Ring Jinghui offers a variety of thick film alumina ceramic metallization rings, the typical thick film include nickle plating, copper plating, gold plating, tin plating and so on through screen printing,...

-

Unit Price:USD 1.65 - 3 / Piece/PiecesBrand:Jinghui CeramicsModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthMetallised Aluminum Oxide Ceramic Ring Metallised aluminum oxide ceramic ring is made of alumina oxides with min. 95% purity, It can be shaped via dry pressing, hot pressing, ISO pressing. In common case, both molybdenum-manganese and Tungsten as a...

-

Brand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:CustomizedTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packagingSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthMetallized Ceramics for Gas Tube Arresters Prime characteristics of metallized ceramic in gas discharge tube 1.High brazing strength, up to 120Mpa after ceramic-to-metal joining 2.Super low leak rate and ideal airtightness, less than 1 x 10-11...

-

Unit Price:0.5~50USDBrand:Jinghui CeramicsMin. Order:Piece/PiecesModel No:Standard or custom-madeTransportation:Ocean,Land,Air,Express,ExpressPackaging:Vacumm packaging with export cartonSupply Ability:200,000pcs/monthPlace of Origin:ChinaProductivity:50,000pcs/monthLarge Size Metallized Alumina Ceramic Ring Metallized ceramic ring is made of high purity of alumina ceramics, a metal coating is applied on one end, or both ends to meet brazing needs. It has metallized- seal strength and hermeticity at ceramic to...

1 1

Product Material

95% alumina + designated surface metallization

|

Features

High strength, air tightness and reliability

|

3 3

Application

Used for vacuum welding with metal

|