Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

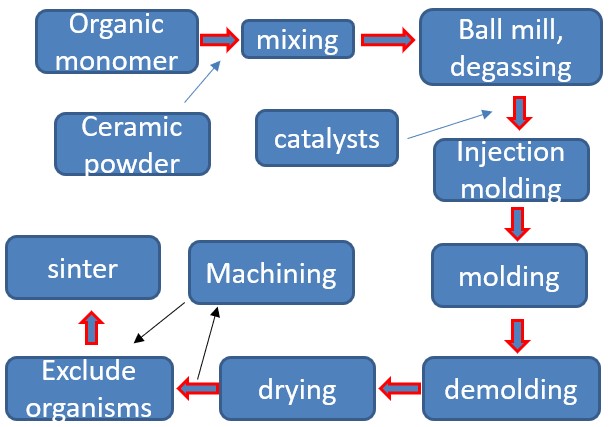

Gel injection molding is a new ceramic molding technique invented in recent years. Some structural ceramic components have used in the process.This method is first of all to disperse the ceramic powder in a solution containing organic monomers, prepare a suspension with a high solid phase volume fraction (>50%), and then inject it into a mold of a certain shape, under certain catalytic and temperature conditions, the organic monomer polymerizes, the system gels, resulting in the suspension solidifying in situ, and finally after drying can obtain a higher strength of the body.

In the process of changing from liquid to solid, the blank does not shrink or shrink very little, and the amount of medium does not change. It can manufacture complex shaped Ceramic parts at net size, with good body uniformity and high strength, its operation process is simple, the content of organic matter impurities in the body is small, and the ceramic sintered body has excellent performance.

Gel injection molding is divided into two categories: one is water-soluble gel injection molding, and the other is non-water-soluble gel injection molding. The former is suitable for most ceramic molding applications, while the latter is mainly suitable for the molding of systems that react with water.

Merit:

(1) Strong ability to apply ceramic powder, no special requirements for powder;

(2) Near-net size molding can be realized, large-size and complex shapes and wall thickness parts can be prepared, and a variety of materials can be selected for the mold;

(3) The molding cycle is short, the wet blank and dry blank strength is high, which is obviously better than the blank made by the traditional molding process, and can be mechanically processed;

(4) Low content of organic matter in the body;

(5) Good uniformity of the performance of the blank and sintered body;

(6) The process is easy to control;

(7) The process and operation are relatively simple, the equipment is simple, and the cost is low.

Shortcoming:

(1) Defects such as bubbles and cracks may occur during the molding and drying process;

(2) Toxicity of organic monomers.

Apply:

Coarse particle system ceramics, advanced refractory materials, ceramic composites, structural ceramics,high precision Structural Ceramic Component ,functional and bioceramics, porous materials and powder metallurgy.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.