Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Advanced ceramic plate have the advantages of outstanding electrical insulation properties, excellent high-frequency characteristics, good thermal conductivity, thermal expansion rate, compatibility with various electronic components, and stable chemical properties. They are more and more widely used in the field of substrates. Alumina ceramics is one of the most widely used ceramics now. With the improvement of the processing accuracy and efficiency of Alumina Ceramic Substrate, traditional mechanical processing methods can no longer meet the needs. Laser processing technology has the advantages of non-contact, flexibility, high efficiency, easy digital control, and high precision, and has become one of the most ideal methods for ceramic processing today.

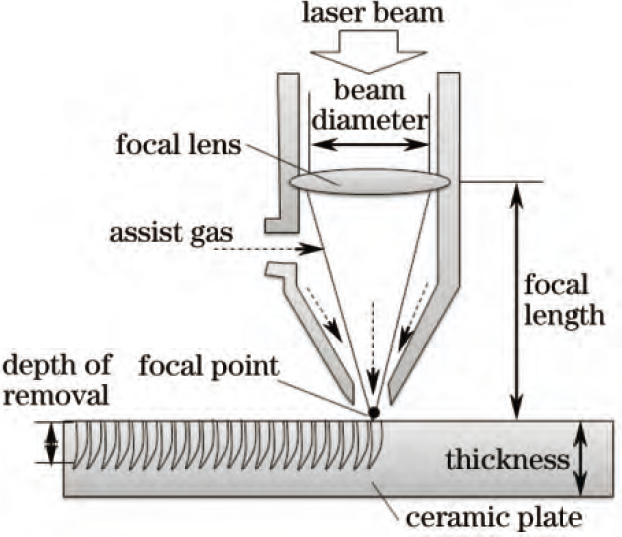

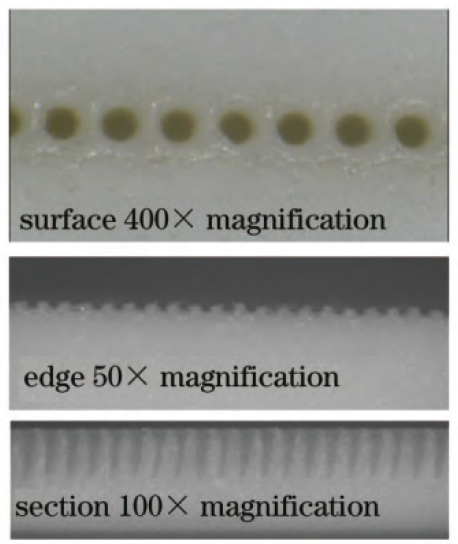

Laser scribing is also called scratch cutting or controlled fracture cutting. The mechanism is that the laser beam is focused on the surface of the alumina Ceramic Substrate through the light guide system, and an exothermic reaction occurs to generate high temperature, ablating, melting and vaporizing the ceramic scribed area. The ceramic surface forms blind holes (grooves) that connect with each other. If stress is applied along the scribe line area, due to the concentration of stress, the material is easily broken along the scribe line accurately to complete the slicing.

In the laser processing of alumina ceramics, in the field of substrate cutting and dicing, CO2 lasers and fiber lasers are easy to achieve high power, relatively cheap, and relatively low processing and maintenance costs compared with other types of lasers. Alumina ceramics have a very high absorptivity (above 80%) for CO2 lasers with a wavelength of 10.6 mm, which makes CO2 lasers widely used in the processing of alumina Ceramic Substrates. However, when CO2 lasers process ceramic substrates, the focused spot is large, which limits the machining accuracy. In contrast, fiber laser ceramic substrate processing allows a smaller focused spot, narrower scribing line width, and smaller cutting aperture, which is more in line with precision machining requirements.

The Alumina ceramic substrate has a high reflectivity of laser light near the wavelength of 1.06 mm, exceeding 80%, which often leads to problems such as broken points, broken lines, and inconsistent cutting depths during processing. Using the characteristics of high peak power and high single-pulse energy of QCW mode fiber laser, the cutting and scribing of 96% alumina ceramic substrates with a thickness of 1 mm directly using air as auxiliary gas without the need to apply absorbent to the ceramic surface , simplifies the technological process and reduces the processing cost.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.