Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

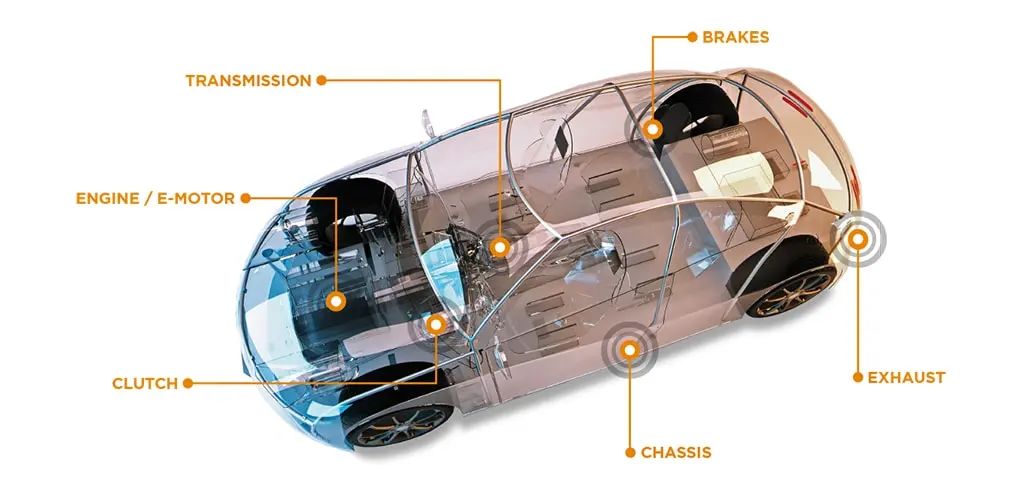

Alumina (Al2O3) substrate is currently the most widely used, the most economical and effective Ceramic Substrate material. It offers excellent electrical insulation, chemical stability, high thermal conductivity, high frequency and other ideal comprehensive performance. In the field of automative industry, the demand for alumina Ceramic Substrates have been increasing year by year due to the rapid development of the industry.

IGBT is one of dominant device in modern power electronic devices, and is internationally recognized as a most representative product of the third revolution of power electronic technology. IGBT is the core device of energy conversion and transmission, which can adjust the voltage, current, frequency, phase, etc. in the circuit according to the signal instructions, and is mainly used in the automobile manufacturing for motor controllers, vehicle air conditioners. In traditional IGBT modules, precision Alumina ceramic substrate is the most universally used substrate. However, due to the relatively low thermal conductivity of Al2O3 Ceramic Substrate and the poor match with the thermal expansion coefficient of silicon, it is not suitable for high power module packaging materials.

Automotive sensors require the parts are that they can be applied to the harsh environment ((high temperature, low temperature, vibration, acceleration, humidity, noise, exhaust gas) unique to automobiles for a long time , as well as should have light weight, good reusability strength, and wide output range. Aluminum oxide ceramic substrate could perfectly withstand high-temperature, corrosion, abrasive and its potential excellent electromagnetic and optical functions, in recent years with the progress of manufacturing technology has been fully utilized, the sensors in alumina ceramic materials can fully meet the above requirements, representing the application of lidar, camera, millimeter wave radar and so on.

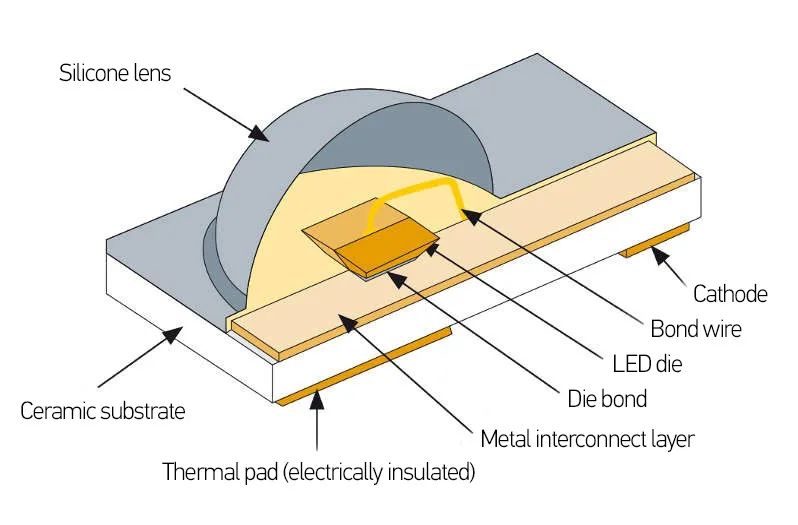

In recent years, LED lighting technology has been far and wide used in automobile manufacturing, such as headlights, taillights, indicators, atmosphere lights, display backlights and so on. The higher power of the LED, the more attention needs to be paid to its heat dissipation problem - if the heat generated by the LED operation can not be effectively dispersed, it will result in the LED junction temperature too high, not only leading to the rapid decay of the LED luminous efficiency, but also the life of the LED device. At present, the use of alumina ceramic substrate is not only low cost, but also can efficiently and environmentally friendly production of high power, high precision, low cost, high adhesion, high surface flatness of LED ceramic cooling substrate, so it has been exstensively used in the LED field.

Although alumina ceramics can meet the rigid supporting requirements and the function of environmental erosion resistance,its theoretical and actual thermal conductivity are low, improving the quality of the substrate product is necessary in order to better meet the requirements of the development of the electronics industry, optimizing the quality of raw material Al2O3 powder, enhancing the value of properties, and choosing first-rank manufacturing process are adopted.

In addition to the selection of raw materials, the forming and sintering process is also a key factor in determining success or failure. In terms of molding technology, injection molding, dry press molding and casting molding are commonly used, but the efficiency of injection molding is high, but it is difficult to make large-size sheet; The product density of dry pressing is high, the flatness of the substrate is easy to guarantee, but the production efficiency is low, the cost is high, and the preparation of ultra-thin substrate is difficult. Casting is a double advantage of high production efficiency and ultra-thin, but it is easy to deform during sintering because of the low density of the billet. Therefore, in order to improve the rate of excellent products of large-size substrates, the industry is focusing on the optimization of sintering methods and the selection of sintering additives.

In short, at the present stage of automotive research and development and production stage has been more and more alumina ceramic substrate materials, but if in the future automotive manufacturing industry will be more alumina ceramic substrate, intelligent ceramic products are introduced and used in the automobile, in many aspects of alumina ceramic raw materials, material evaluation and utilization technology need to continue to be studied.

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.